M: 0086-138 6858 3040

T: 0086-577-6319 2618

F: 0086-577-6367 7038

Wechat: zhang_xinchun

Skype: zhang_xinchun

Whatsapp: 008613868583040

E: sales@tf-machinery.com

S: Http://www.tf-machinery.com

A: Wenzhou, Zhejiang, China

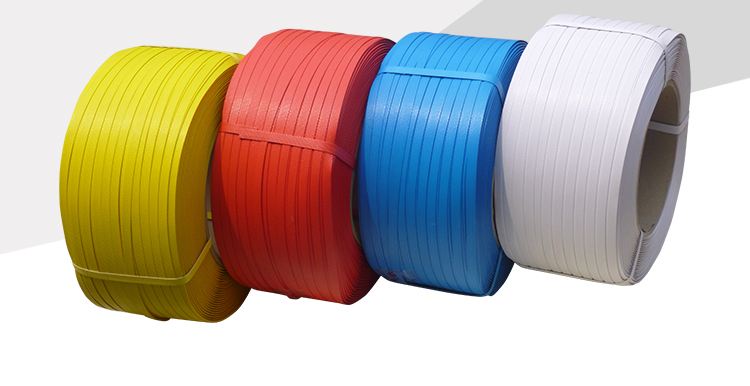

PP Strap Extrusion Line

Application:

To produce PP strap for the needs of carton, wooden box, tobacco, paper industry, clothing, food, fruit, refrigerator, washing machine, color TV and other industries.

Advantages:

● Suitable for various of formula of PP material, such as, PP granule raw material, powder raw material, recycled material, their mixture material, etc.

● High production capacity, max. speed is up to 300 m/min.

● Good forming.

● Inverter control, more energy-efficient.

● Easy operation and maintenance, stable running, long working life.

● Safety and environmental protection, low noise, no pollution.

● Best economic benefit.

● The use of the environment: Not afraid of moisture, corrosion resistance, acid and alkali resistance, water absorption and hygroscopic small, after immersion does not reduce the strength, the use of safe operation and other advantages.

● Small elongation: No slack, large specific strength, can maintain tension for a long time, so as to ensure that the goods have excellent impact resistance in long-distance transportation.

● Strong temperature resistance: Melting point is 260℃, 120 ℃ below the use of deformation, do not fade, do not soften, between -50℃- 100℃, maintain good stability.

● High degree of automation: After the polypropylene particles into the equipment, the material is heated and fused, extrusion into belts, cooling, baking, stretching, printing, embossing, winding and other processes synchronous control, automatic completion.

Composition of the Line

|

Standard items

01) Vacuum automatic loader, 1 set |

Optional items

01) PLC and HMI control system |

Technical Data

|

Model |

SJ-PP-G110/4 |

| Raw material |

PP (Polypropylene) |

|

Extruding screw type |

110/30 |

| Number of extrusion orifice | 4 pcs |

| Width of strap | 8-15mm |

| Thickness of strap | 0.5-1.2mm |

|

Max. extrusion capacity * |

250 kg/hr |

|

Number of winder |

6 heads |

|

Max. linear speed * |

300 m/min |

|

Inner diameter of winding core |

Ø200-250 mm |

|

Winding width |

180 mm |

|

Winding diameter |

Ø600-650 mm (approx. 10kg) |

|

Power supply |

380V / 3P / 50Hz / A.C. |

|

Installed total power |

205kw |

| Power consumption (approx.) |

100kw |

| Overall dimension (L×W×H) | 30,000×1,500×3,000 |

Remark:

* The data depends on processing specification and the physical & chemcial property of material.

** Specification and dimensions are subject to change without prior notice.

*** Special specification and versions on request.

For any questions, requirements or help, please contact with us freely. >>