M: 0086-138 6858 3040

T: 0086-577-6319 2618

F: 0086-577-6367 7038

Wechat: zhang_xinchun

Skype: zhang_xinchun

Whatsapp: 008613868583040

E: sales@tf-machinery.com

S: Http://www.tf-machinery.com

A: Wenzhou, Zhejiang, China

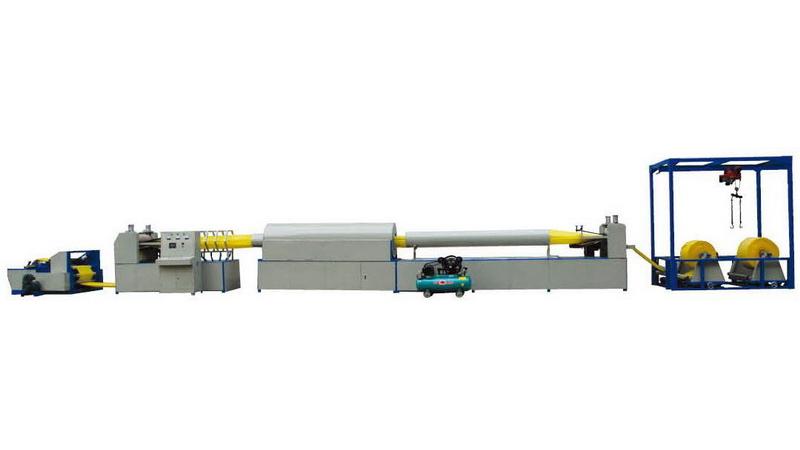

PE Film Liner Inside Laminating Line

Application:

To heat PP/HDPE woven tubular fabric with PE film liner, and laminate PE film liner with PP/HDPE woven tubular fabric, to make sugar bag, feed bag, fertilizer bag, chemicals bag, etc.

Advantages:

● High efficiency

● Low maintenance cost

● Operator friendly

● Best economic benefit

Composition of the Line

|

Standard items

01) Double station unwinding unit with hoist |

Optional items

1) Air compressor station |

Technical Data

|

Model |

TF-NMF/650 |

| Width of woven fabric |

350 - 650mm |

|

Max. dia. of unwinding |

1200mm |

| Length of heating tunnel | 3200mm |

| Heating power | 36kw |

| Heating temperature | 200℃ |

|

Max. speed of laminating * |

50m/min |

|

Max. dia. of rewinding |

1200mm |

|

Power supply |

380V / 3P / 50Hz / A.C. |

|

Total power of motor |

14.5kw |

| Installed power |

50.5kw |

|

Power consumption (approx.) |

35kw |

|

Air compressed supply |

1.53m/min, 0.6 - 0.8MPa |

| Overall dimension (L×W×H) | 19000×2000×3500 |

Remark:

* The data depends on processing specification and the physical property of material.

** Specification and dimensions are subject to change without prior notice.

*** Special specification and versions on request.

For any questions, requirements or help, please contact with us freely. >>