M: 0086-138 6858 3040

T: 0086-577-6319 2618

F: 0086-577-6367 7038

Wechat: zhang_xinchun

Skype: zhang_xinchun

Whatsapp: 008613868583040

E: sales@tf-machinery.com

S: Http://www.tf-machinery.com

A: Wenzhou, Zhejiang, China

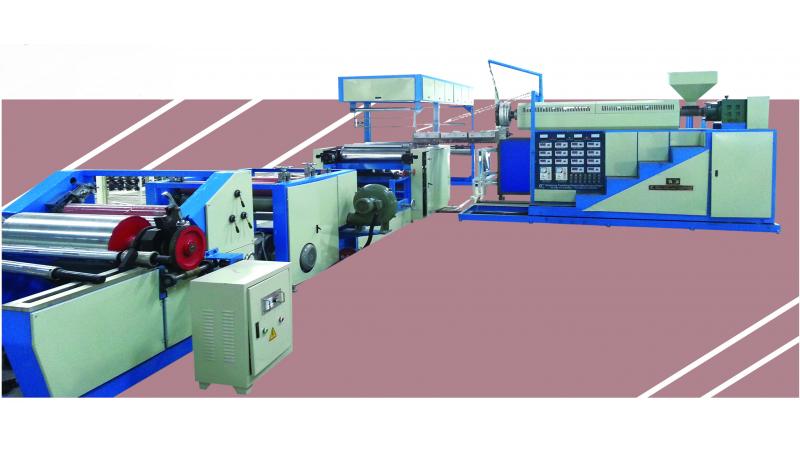

2: Plastic Extrusion Coating and Laminating Machine

Application:

To coat PP/LDPE film on PP/HDPE woven fabric, kraft paper, non-woven fabric, etc, or laminate BOPP film, kraft paper with PP/HDPE woven fabric or non-woven fabric.

To produce coated/laminated woven bag, cement bag, rice bag, flour bag, pet food bag, animal food bag, fertilizer bag, chemical bag, etc.

Advantages:

● Good coating adhesion

● Low energy consumption

● Low maintenance cost

● Operator friendly

● Best economic benefit

Composition of the Machine

|

Standard items

01) Granule automatic loader |

Optional items

01) Dosing unit |

Technical Data

| Model | SJ-FMF800-90I | SJ-FMF800-90II |

| Extruder | E90/28 | E90/28 |

| Diameter of screw | 90mm | 90mm |

| Ratio of screw L/D | 28:1 | 28:1 |

| Motor of extruder | 22kw | 22kw |

| Max. extrusion capacity * | 60kg/h | 60kg/h |

| Width of die | 1000mm | 1000mm |

| Width of coating | 350 - 800mm | 350 - 800mm |

| Thickness of coating | 0.01 - 0.05mm | 0.01 - 0.05mm |

| Laminating speed * | 20 - 100m/min | 20 - 100m/min |

| Printing speed * |

- |

20 - 80m/min |

| Length of cooling roller | 900mm | 900mm |

| Width of processed material | 300 - 750mm | 300 - 750mm |

| Range of unwinding web guide | ±100mm | ±100mm |

| Innder dia. of unwinding/rewinding core | 76mm | 76mm |

| Max. dia. of unwinding/rewinding | 1200mm | 1200mm |

| System installed power | 70kw | 70kw |

| Normal operational power (approx.) | 45kw | 45kw |

| Overall dimension (L×W×H) | 11000×5500×2500 | (11000)×5500×2500 |

Remark:

* The data depends on specification & quality of processed material, thickness of coating and the physical & chemical property of raw material.

** Specification and dimensions are subject to change without prior notice.

*** Special specification and versions on request.

For any questions, requirements or help, please contact with us freely. >>